Magnetoactive Boron−organo−silicon oxide Polymers (MBP) are a mixture of so called “silly putty” and the same (5 micrometre diameter) CIP as used in MRF and MAP. With this combination, the particles are no longer secured within the polymer matrix but may migrate in the direction of the magnetic field.

Certain organo-silicon oxide polymers demonstrate viscoelastic-plastic characteristics such as rheopexy. The combination of dimethylsiloxane and boric acid dates back to two patents filed during the 1940's. The original compound comprised 65% dimethylsiloxane (hydroxy-terminated polymers with boric acid), 17% silica (crystalline quartz), 9% Thixotrol ST (castor oil derivative), 4% polydimethylsiloxane, 1% decamethyl cyclopentasiloxane, 1% glycerine, and 1% titanium dioxide and the majority of modern compounds deviate little from this.

One of the main manufacturers is Crayola, though there are several others. The material is marketed as a toy under the name “Silly putty” or "bouncing putty" or in German as "Hüpfender Kitt". Industrial uses including deburring and pollishing.

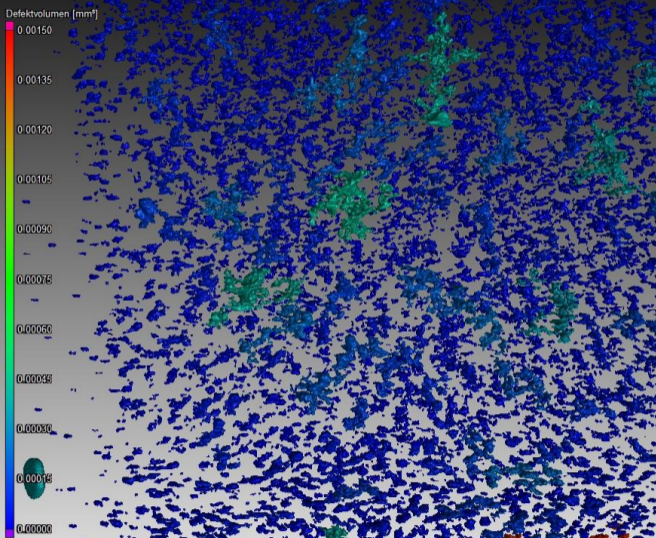

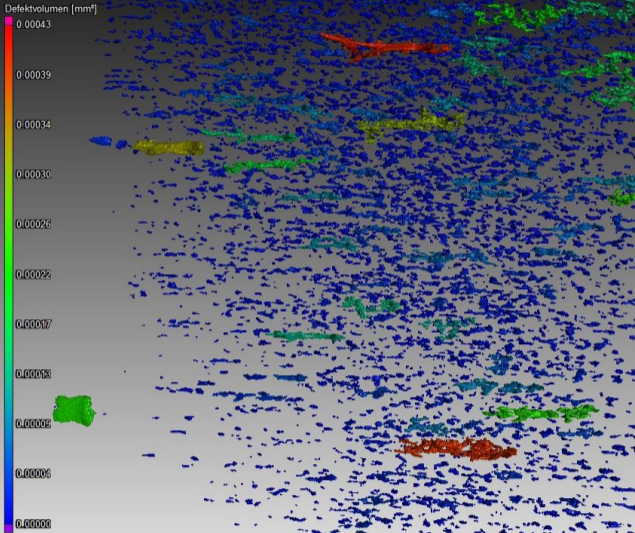

The combination of carbonyl iron particles with organo-silicon oxide polymers does not result in an elastomer as with traditional PDMS materials because organo-silicon oxide polymers are visco-elastic. Low strain rate deformation is inherently plastic rather than elastic. This means that any magnetic content will tend to move in an applied magnetic field, hindered only by the visco-elasticity of the matrix. Whereas in the case of a magnetic elastomer, the magnetic field induced displacement of a magnetic particle is always limited by the elasticity of the polymer matrix in which the particles are held.

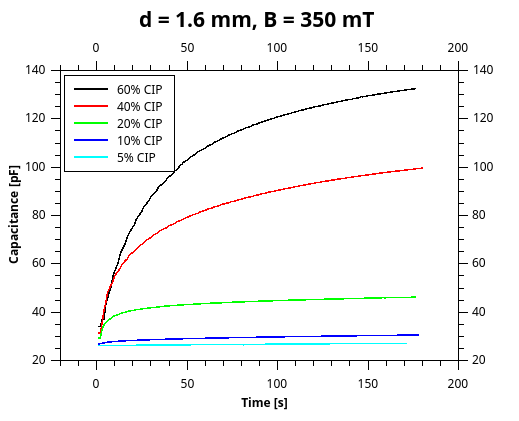

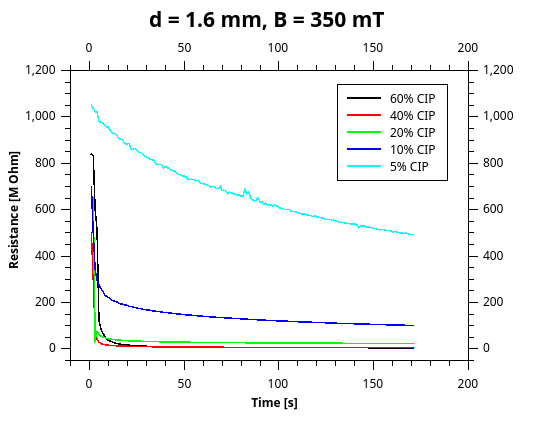

This results in an interfacial magneto-capacitance greatly superior to that achievable using MAP. Furthermore, the electrical resistance decreases dramatically. Without a magnetic field the material is highly insulating and a few millimeters can withstand several thousand volts. With the application of a magnetic field, the material switches into a conductive condition enabling current flow.

Due to their inherent elasticity, MAP are not really suitable for use in shape memory applications. MBR on the other hand has visco-elastic-plastic properties which also demonstrate rheopexy (shear thickening). When suspended in a homogeneous magnetic field (created by the system developed in the RADICALS project), the MBP will hold the imprint of an object for several hours. The onset of relaxation commences withing minutes following magnetic field removal. The rheopectic nature of the materials allows abrupt form removal without imprint distortion.

There are many interesting applications for MBP and research is continuing with the DFG funded project Mr.Bos.