Magnetoactive polymers (MAP) contain magnetically susceptible particles in the same way as magnetorheological fluids. However, the movement of the particles is restricted by the elasticity of the polymer matrix. Various soft magnetic filler materials can be used for example carbonyl iron powder (CIP), Nickel etc. When hard magnetic materials such as NdFeB or SmCo particles are used it is possible to magnetize the resulting polymer. Matrix materials are usually elastomers such as polydimethylsiloxane (PDMS) or polyurethane. Usually two component (base and curing agent) mixtures are used which polymerize over a period of minutes or hours. Degassing in a vacuum is usually carried out immediately after mixing.

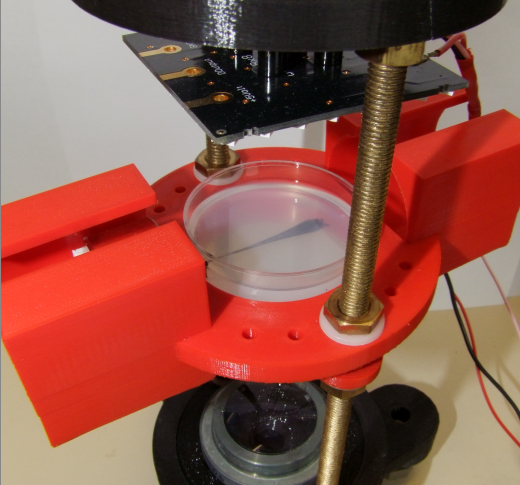

In order to 3D print silicone parts a special extruder is required. At the time of the research no such extruder existed on the market. The one shown here was developed in the MRU.

Internal structures can also be created by applying a magnetic field to displace the magnetic filler during the curing process. When used with 3D printing (x, y, z), the magnetic filler can be orientated or the diffusion gradient controlled in all three axes (θ, φ, ψ) resulting in 6D printing.

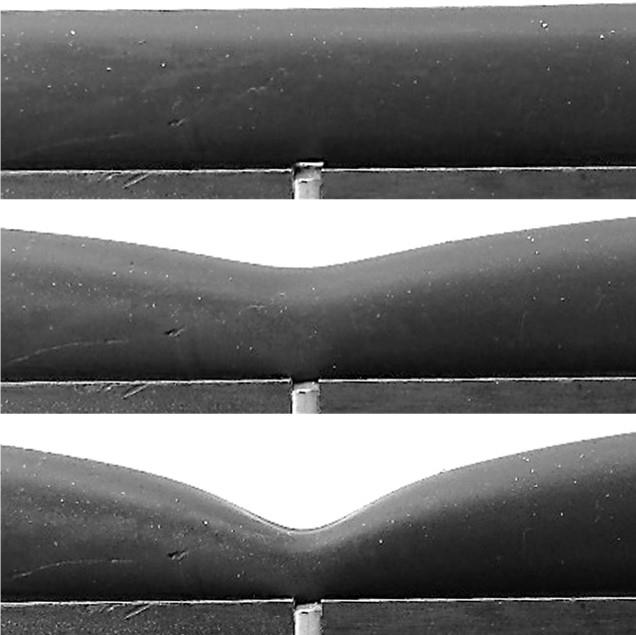

One interesting property is the increase in Young’s modulus of an MAP when it is subjected to a magnetic field. Another effect is to exploit magnetodeformation such as the squeezing of a conduit to restrict fluid flow. Using a row of 3 discrete electromagnets, a simple peristaltic pump can be created.

The magnetization of hard magnetic materials in an MAP creates a flexible magnet. However, when combined with an electret a magnet results which can attract almost any material, not just magnetically susceptible parts.

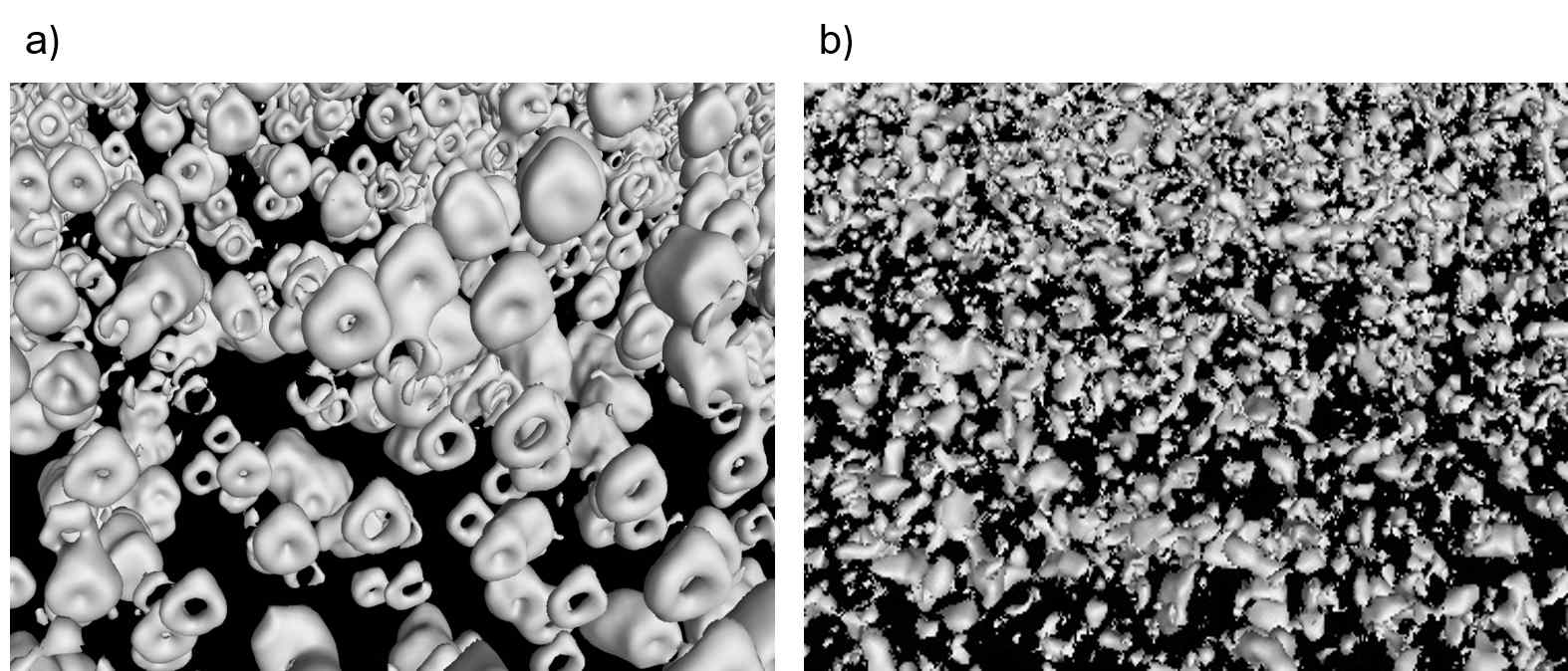

Most researchers have hitherto concentrated in putting as much magnetic filler into the mixture as possible. Most MAPS contain between 20% and 90% wt. The MRU was the first research group in the world to move in the other direction – sparsely populated matrix MAP with between 1% and 3% wt. This resulted in some extremely interesting effects.

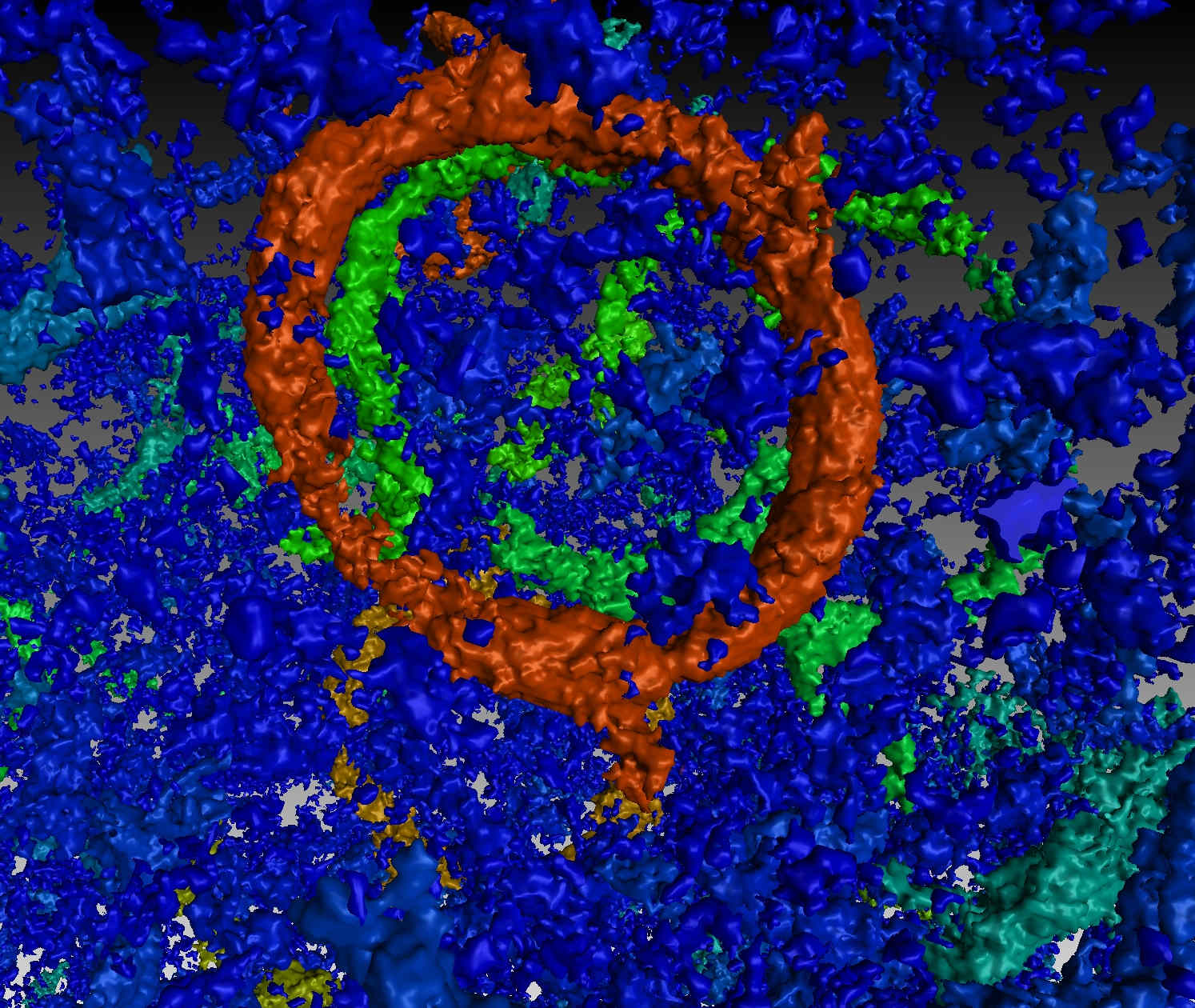

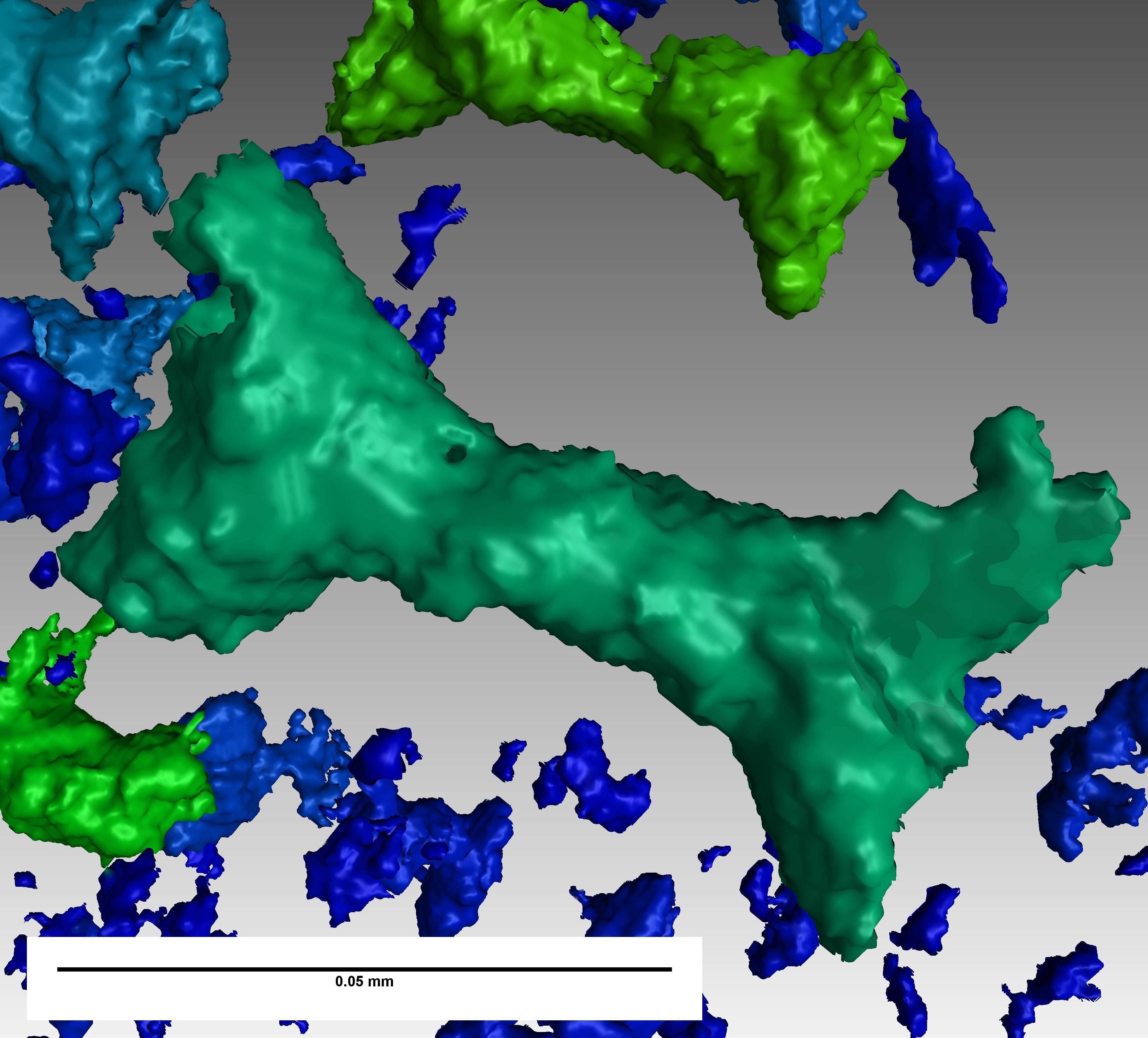

As cavities rise against gravity during the degassing process, they collect particles around their circumference until a certain mass has been reached at which point shedding occurs. With approximately 2% wt CIP, this results in toroidal structures.

If the CIP content is increased to slightly more than 2% wt, then many of the rings meet at which point the entire particulate mass tends to fall into the centre resulting in a capillary doublet.

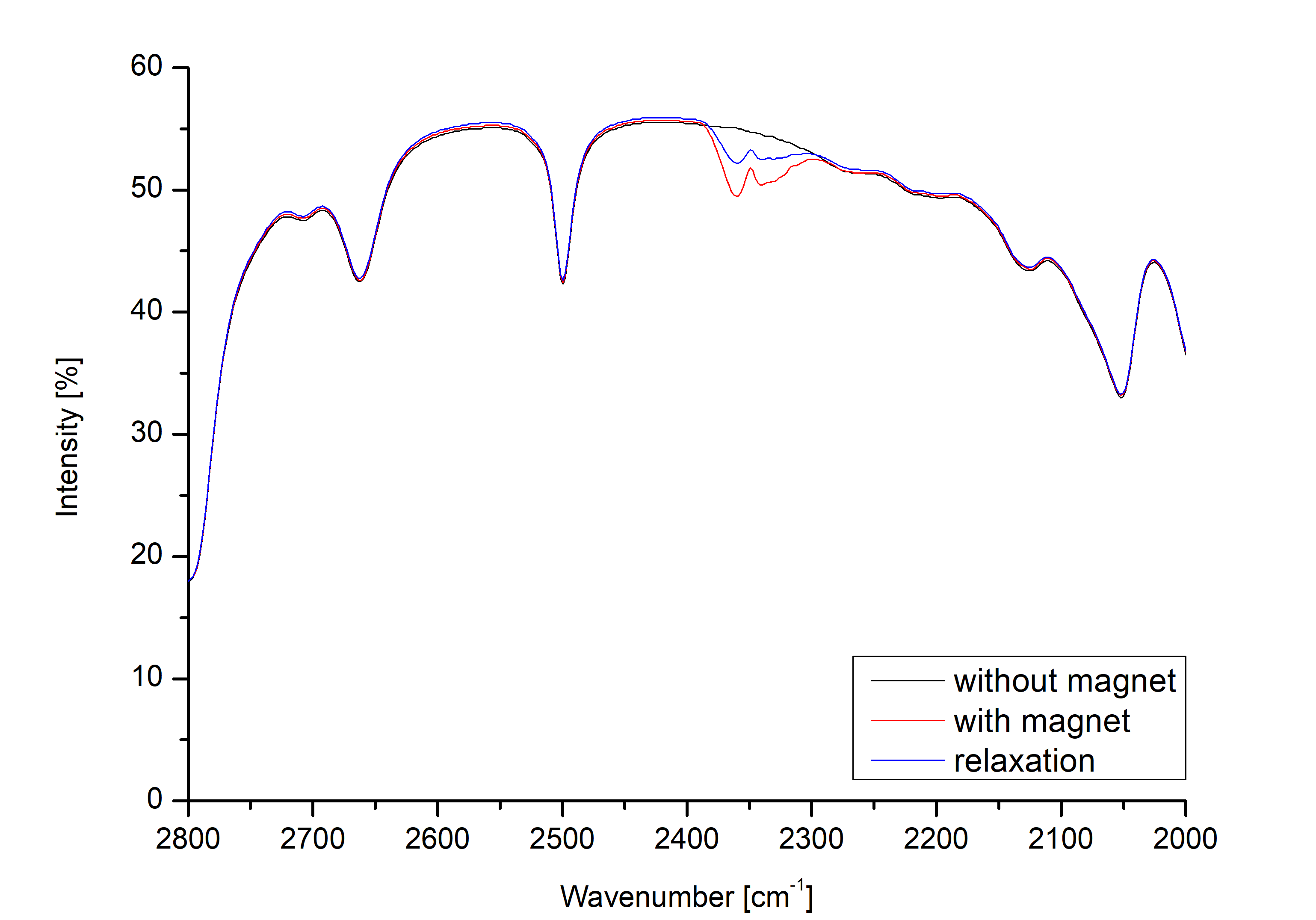

Because the relative permittivity of the PDMS matrix is not a function of a magnetic field, no true magneto-dielectric effect is possible. However it is possible to change the electrical capacitance of the MAP by means of an applied magnetic field. This is known as interfacial magneto-capacitance and is a result of proximity reduction between particles. Although there are no observable magneto-optical effects using light transmission through MAP, at infra-red frequencies a reaction with atmospheric CO2 is observable at a wavelength of 4.255 micro metres.

There are many interesting applications for MAP and research is continuing at the MRU.