Electroadhesion has a long history and has advanced much over the years. Improvements have resulted in increased prehension force but one problem has remained – that of rapid and controlled ejection of the workpiece at the target position. Dielectric remanence results in residual charge which tends to retain the workpiece long after the high voltage supply has been removed. Placing a short circuit across the terminals does not help because the charges concerned are a function of the local electric field across the individual charges structures within the dielectric, not the applied electric field. For magnetoadhesion this problem is easily mitigated. The addition of a thin polymer layer over the gripping head introduces a non-magnetic gap which significantly reduces the effects of magnetic remanence.

In the case of micro components acoustic vibration can help. For larger workpieces this is less useful. Many attempts have been made to expedite release, including the use of pneumatics, mechanical assistance etc.

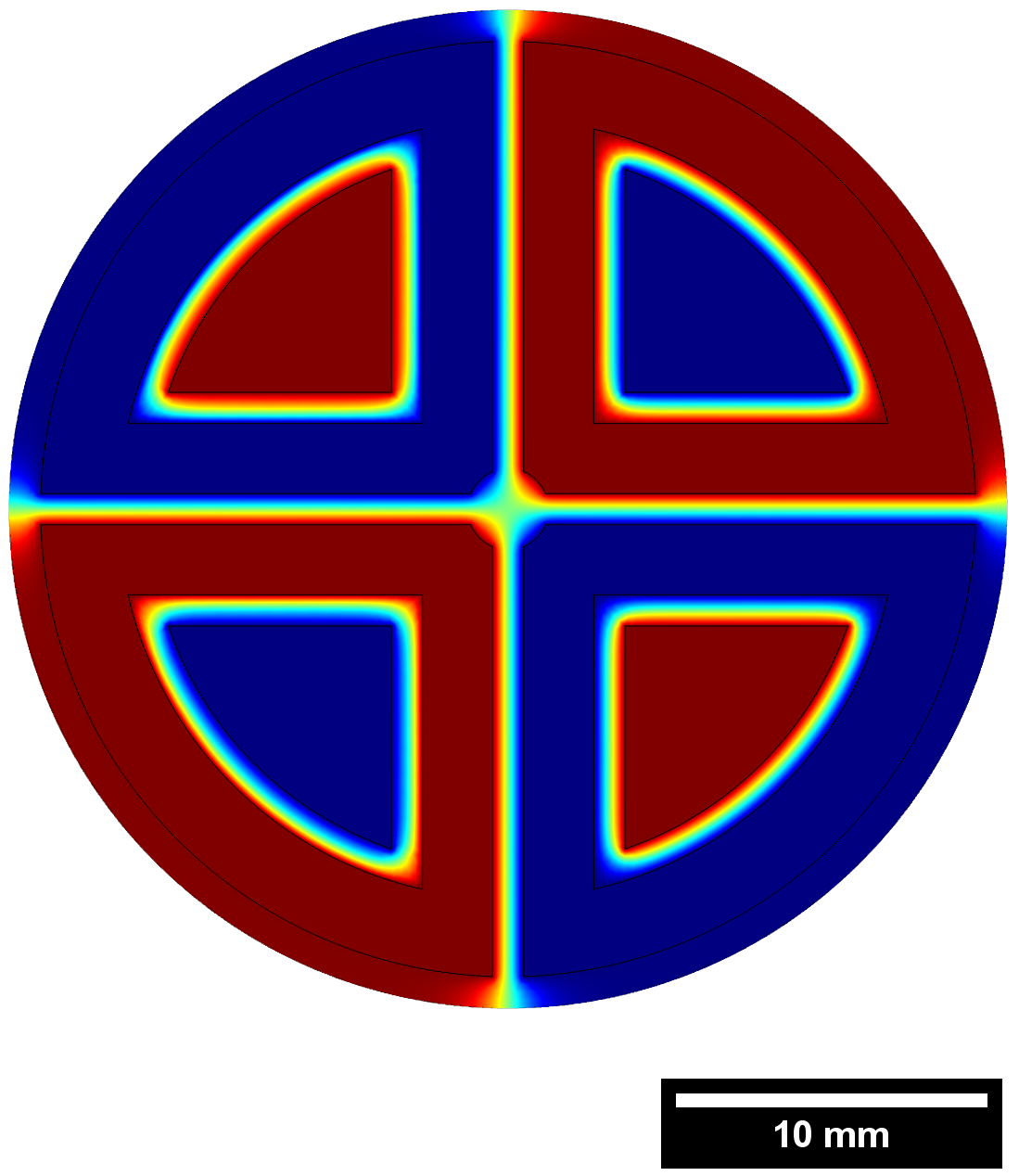

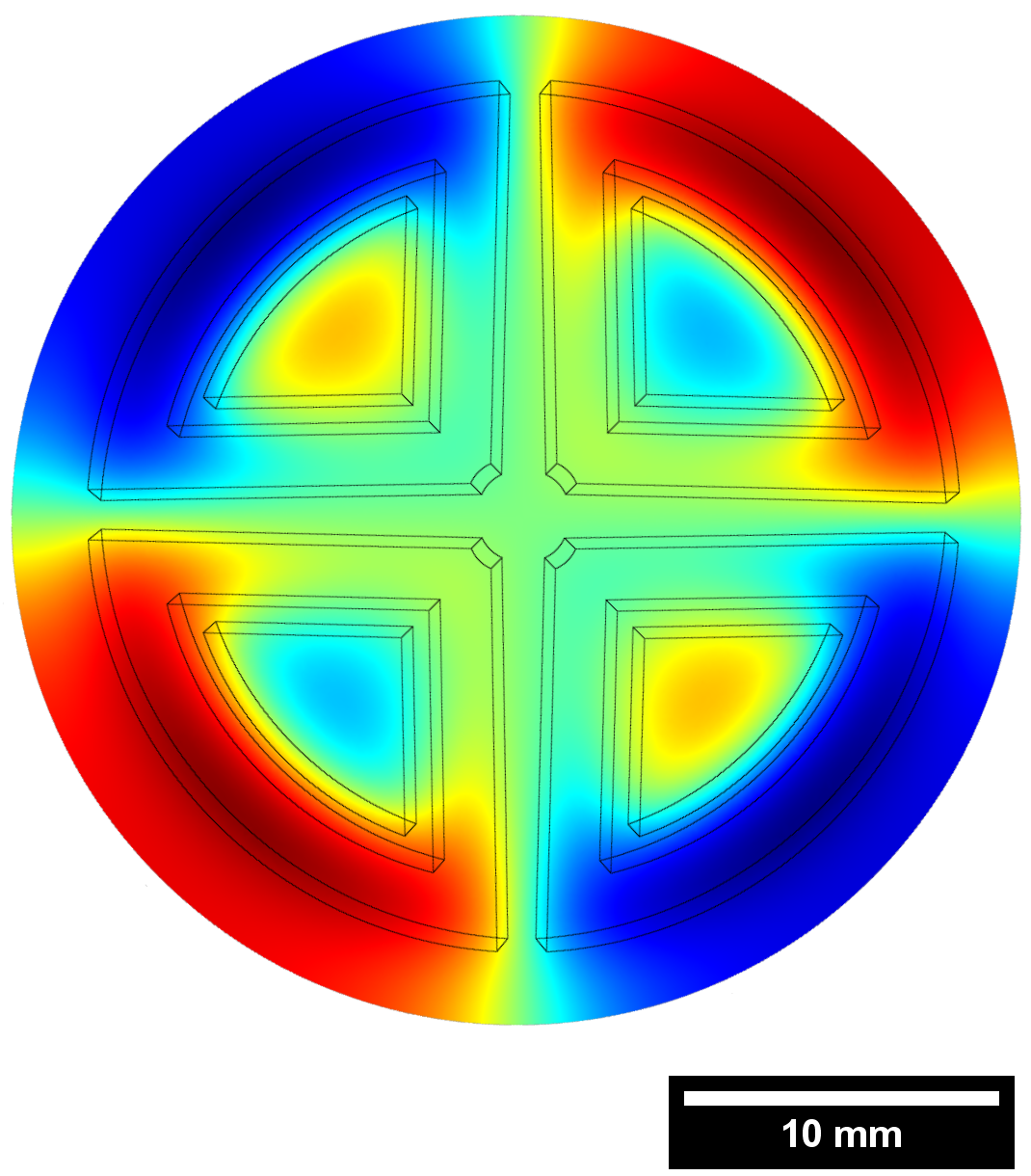

Recently, the combination of magnetoactive polymers (MAP) and electroadhesive dielectrics has produced a very successful solution. A simulation of the EAG without the magnetic field applied and the central deformation due to the influence of a magnetic field, can be seen below:

Given that both the electroadheson and the MAP are based on PDMS, it is possible to integrate all components including the electrically conducting paths within one PDMS substrate.